Core6 GRP Pultruded grating offers a fast, safe and effective flooring solution to high load capacity access areas. Pultruded grating is manufactured by glass fibres being pulled through a resin bath. Its is then heated to cure the pultruded shape. Load bearing bars are drilled to accommodate the interlocking tie bars. Both bars are then assembled in a jig and bonded together to make the finished panel of grating.

This manufacturing process produces parts that are generally 65% fibreglass and 35% resin (by weight). As a result, this process produces the strongest composite gratings which are often specified in high traffic areas.

Specification

- Corrosion resistant

- Slip resistant – anti skid surface

- Light weight – Density 4 times less than steel

- Low maintenance (no rusting, no painting)

- Non-conductive – does not carry electric current

- Radio Frequencies (FR) and Electromagnetic transparency

- Aesthetic appealing

- Impact resistant

- UV resistant

- Easy to cut and fabricated – hand cutting tools required only

- Lowest in life cycle cost

Gallery

- Pultruded Core-6 GRP Grating

- 38mm Pultruded Core-6 GRP Grating

- Pultruded Core-6 GRP Grating

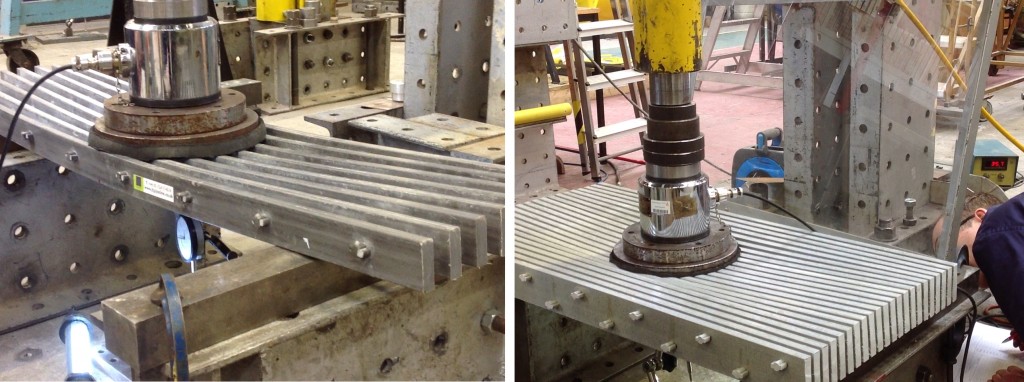

High Load Capacity (HLC)

Impact testing on Pultruded grating

Oil & Gas

Oil & Gas Rail

Rail Marine

Marine Civil &

Civil & Process &

Process & Power &

Power &