This station refurbishment required a new set of dagger-boards to replace the old rotten wood daggers that were past their best.

Continue reading

Category Archives: News

Delivering products with zero electrical conductivity

In the power, Rail and utilities sectors one of the biggest risks is electrical conductivity. As a result materials need to be chosen with great care to keep the risk of accidents to a minimum. Ladders, handrails, gates, fencing and walkways all need to have good electrical resistance to prevent any accidental currents from travelling and putting more people on the site in harm’s way. Continue reading

Core6 GRP is a great alternative to steel for walkways

Open grated walkways are utilised in a wide array of settings. They are designed to prevent water from pooling and to provide a safe surface for people to walk on. Walkways must be sturdy, corrosion resistant, and slip-resistant to prevent accidents. Continue reading

Why is Core-6 GRP excellent for marine applications?

Marine applications create a wide array of challenges for construction materials. The salt air can cause corrosion resulting in accelerated wear on anything that is not highly resistant. In addition the moisture can make surfaces slippery creating potential accident areas. Weight can also be an issue in dockside and offshore settings and Core-6 offer materials that are light weight whilst still durable. Continue reading

Core6 GRP offers H&S benefits in different settings

Regardless of the market, whether it is oil and gas, rail, construction, or industrial and processing, there are always health and safety (H&S) requirements to meet. Every workplace should be safe for employees to inhabit at all times, keeping the risks to an absolute minimum. Continue reading

Why use Core6? What makes our GRP products stand out?

Core6 has grown into a market leader in GRP products over the last forty years. We have achieved this by focusing on quality at all times and constantly expanding our knowledge of and experience with the material. As a result, when we are presented with new challenges we are always confident of finding an effective solution. Continue reading

Core6 and Roperhurst have entered into a new partnership

A recent exciting development is the formation of the partnership between Roperhurst Limited, a long standing plastics specialist based in Barry and ourselves. Roperhurst with previous experience of the Core6 product range have committed to a significant stock with the objective of selling products ex-stock but also full fabrications throughout Wales and along the M4/M5 corridor. Continue reading

What is GRP and why is it useful for so many applications?

GRP stands for Glassfibre Reinforced Plastics. High strength glass-fibres are integrated into the product at the manufacturing stage meaning composite materials deliver impressive high strength-to-weight properties and by choosing from a variety of speciality resins, the finished product is able to provide a long service life in the harshest of environments. As a result composites are useful for an incredible range of applications in a variety of settings. Continue reading

Core-6 Composites attends ‘Composites in Rail’ showcase

Core-6 Composites, the UK’s largest stockist of Composite Grating and Access products will be showcasing their products at the up and coming ‘Composites in Rail’ showcase on 12th May at the University of Manchester.

Organised by Composites UK, the showcase focuses on how the rail industry is embracing fibre-reinforced polymer composites which are used in both infrastructure and rolling stock applications.

Composite bridge structures are favoured for their lightweight and durable properties and can be pre-fabricated off-site. Disruption to service is minimal as replacements of foot or road bridges over the network can be installed overnight. Other infrastructure applications include track-beds gantries, lineside furniture and platform services.

Core-6 Composites have been supplying and fabricating FRP grating structures since 2007 to various industry sectors. Specialising in offering pre-fabricated, made-to-measure packages, Core-6 Composites can consult, design and fabricate any FRP structure to exact requirements within a short timescale.

Core-6 Composites pride ourselves on our professionalism and technical product knowledge. Our highly skilled staff can offer advice and support throughout your repair or maintenance project.

Visit our stand at ‘Composites in Rail’ or call our head office today on 0800 876 666 8 to arrange a visit from one of our sales representatives covering the UK.

Alternatively email sales@core-6.co.uk or visit our website www.core-6.co.uk

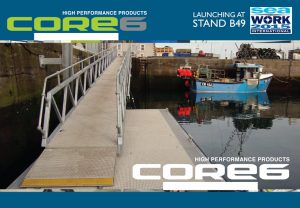

Seawork International Marine & Workboat exhibition

Core6 – the new generation of composite materials was launched by John Bell Pipeline Equipment Company Limited at the Seawork International Marine & Workboat exhibition at the Port of Southampton from the 16 – 18th June. John Bell Pipeline will be showcasing the strength, durability and diversity of Core6 products which can be used in highly corrosive applications where health & safety, non-slip surfaces and weight-saving is a priority.

Core6 is a specialist composite product used for flooring and access products which has been supplied by John Bell Pipeline to the Marine, Oil & Gas, Subsea & Utilities industries since 2007.

Previous projects have serviced marinas & jetty’s, offshore platforms, distilleries and national gas supply sites with GRP non-slip flooring & handrails as well as subsea manifolds, dropped object covers, cable trays and man whole covers.

Core6 products are made from fibreglass reinforced plastic (GRP/FRP) making them extremely lightweight, easy to assemble, non-corrosive, anti-slip and non-conductive. These benefits provide a cost effective, low-maintenance solution for repair and maintenance requirements both on and off-shore. Core6 grating and panels have no scrap value, can be fabricated to any custom size and are available with fine, medium and coarse grit surfaces to suit your level of non-slip needs.

Ian Campbell, Business Development Manager for Core6 commented ‘Eight years after the conception of our GRP division we have decided to give this product range a stand-alone brand identity to heighten its profile in the marketplace. Originally focused on the supply of Linepipe equipment to the Oil & Gas industry, John Bell Pipeline diversified their scope of supply and now supply various industries including Marine, Utilities and Subsea. Sales have seen a promising increase over the past three years and following the opening of our GRP fabrication facility in June 2013 we now have increased capacity for larger and more complex projects.’

Arrange a visit by one of our experienced sales team to discuss the Core6 composite range, assess your requirements and provide you with a tailored quote for a cost-effective, long term solution to your needs.

Call 0800 876 666 8 and ask to speak to our Core6 GRP department or email your enquiry to sales@jbpipeline.co.uk.

Oil & Gas

Oil & Gas Rail

Rail Marine

Marine Civil &

Civil & Process &

Process & Power &

Power &